Fruehauf developed 1000's of patents and products styles customized for every industry.

These five trailer types were the most basic of products and easily adapted

Click the hyperlinked photos or title for more info

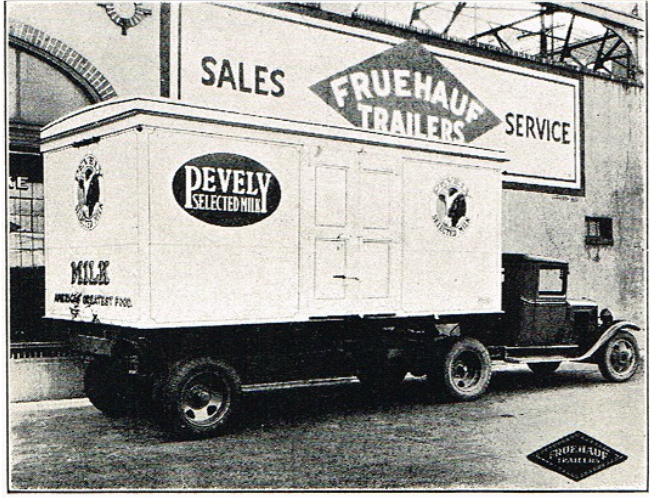

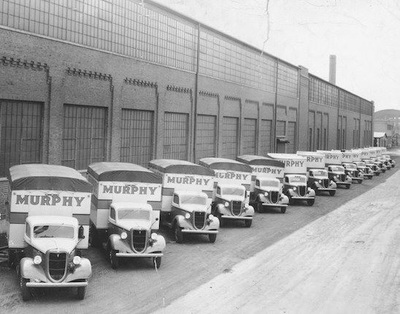

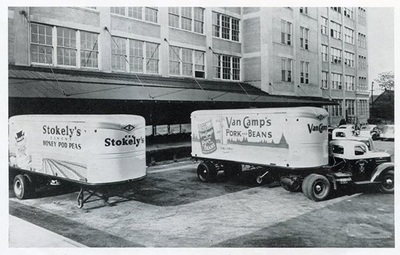

CLASSIC FREIGHT VANS

The Fruehauf Dry Freight van semi-trailer changed over the 85 years they were produced. They included customized semi-trailers for every industry with modifications tailored to order. Freight vans came in corrugated steel vans, drop-frame furniture vans, lightweight aluminum vans and stainless steel vans. Fruehauf's chassis and light wall system gave customers a competitive edge. In the late 1950’s, Roy Fruehauf emphasized, “Our large research and engineering department is constantly making improvements and suggesting changes. And we are always trying to increase payload capacity by decreasing the weight of the semi-trailer without sacrificing strength.” For more on the classic van......

The Fruehauf Dry Freight van semi-trailer changed over the 85 years they were produced. They included customized semi-trailers for every industry with modifications tailored to order. Freight vans came in corrugated steel vans, drop-frame furniture vans, lightweight aluminum vans and stainless steel vans. Fruehauf's chassis and light wall system gave customers a competitive edge. In the late 1950’s, Roy Fruehauf emphasized, “Our large research and engineering department is constantly making improvements and suggesting changes. And we are always trying to increase payload capacity by decreasing the weight of the semi-trailer without sacrificing strength.” For more on the classic van......

DUMP TRAILERS

August Fruehauf was the first semi-trailer manufacturer to bring the use of hydraulics to freight transport in the 1920’s. Lift gates could be lowered or raised for easy loading and unloading. Later, the Fruehauf engineers used hydraulics to create dump trailers. Simple utility trailers were modified with hydraulics to permit the unloading of bulk contents using gravity instead of manpower. Multiple axles were added to increase weight payload. Road building, mining and other heavy hauling industries benefited from these innovations. For more on dump trailers......

August Fruehauf was the first semi-trailer manufacturer to bring the use of hydraulics to freight transport in the 1920’s. Lift gates could be lowered or raised for easy loading and unloading. Later, the Fruehauf engineers used hydraulics to create dump trailers. Simple utility trailers were modified with hydraulics to permit the unloading of bulk contents using gravity instead of manpower. Multiple axles were added to increase weight payload. Road building, mining and other heavy hauling industries benefited from these innovations. For more on dump trailers......

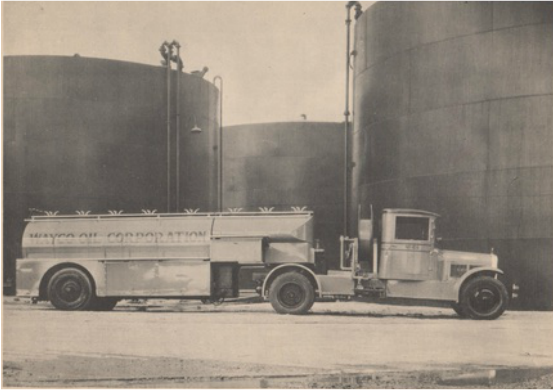

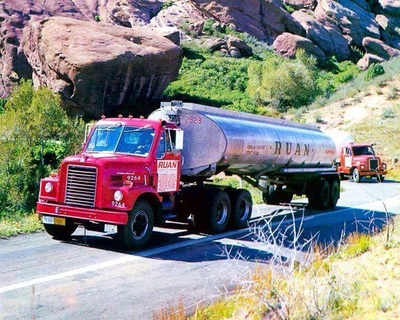

TANKER SEMI-TRAILER

Businesses needing to transport commodities in bulk wanted an enclosed semi-trailer for liquids or dry bulk cargo. Fruehauf designed the first tank trailer for flour. One of their largest customers at the time was Quaker Oats. This tanker concept was then used for milk and other liquid foods, petroleum products and industrial chemicals. Compartments were designed inside the large tanks. This prevented “slosh” or the forward momentum of the liquid sending the stopped or braking trailer against the driver’s will. Tank trailers were made out of steel, aluminum, stainless steel and other materials. Some were insulated, pressurized or even refrigerated. For more on the tanker trailer.....

Businesses needing to transport commodities in bulk wanted an enclosed semi-trailer for liquids or dry bulk cargo. Fruehauf designed the first tank trailer for flour. One of their largest customers at the time was Quaker Oats. This tanker concept was then used for milk and other liquid foods, petroleum products and industrial chemicals. Compartments were designed inside the large tanks. This prevented “slosh” or the forward momentum of the liquid sending the stopped or braking trailer against the driver’s will. Tank trailers were made out of steel, aluminum, stainless steel and other materials. Some were insulated, pressurized or even refrigerated. For more on the tanker trailer.....

REFRIGERATION TRAILERS

Railroads were using refrigeration in their railcars as early as 1877 and these railcars were built in Detroit. William Davis patented a refrigerator car that employed metal racks to suspend animal carcasses above a frozen mixture of ice and salt. In 1868, he sold the design to George H. Hammond, a Detroit meat packer, who built a set of cars to transport his products to Boston using ice from the Great Lakes for cooling. August Fruehauf used this technology to adapt a semi-trailer for transporting perishable foodstuffs in the early 1920s. These units had four- and six-ton capacities and were generally used to haul cans of ice cream. After the cargo was loaded, a trap door on the roof of the trailer was opened to allow pulverized ice and salt to enter through spouts keeping the cargo cold. This was later improved creating vents in the front and back of the semi-trailer to allow air in during travel, which was cooled by the ice. Metal floors were grooved so that melted ice water would be drained out the back. For more on the reefer trailer......

Railroads were using refrigeration in their railcars as early as 1877 and these railcars were built in Detroit. William Davis patented a refrigerator car that employed metal racks to suspend animal carcasses above a frozen mixture of ice and salt. In 1868, he sold the design to George H. Hammond, a Detroit meat packer, who built a set of cars to transport his products to Boston using ice from the Great Lakes for cooling. August Fruehauf used this technology to adapt a semi-trailer for transporting perishable foodstuffs in the early 1920s. These units had four- and six-ton capacities and were generally used to haul cans of ice cream. After the cargo was loaded, a trap door on the roof of the trailer was opened to allow pulverized ice and salt to enter through spouts keeping the cargo cold. This was later improved creating vents in the front and back of the semi-trailer to allow air in during travel, which was cooled by the ice. Metal floors were grooved so that melted ice water would be drained out the back. For more on the reefer trailer......

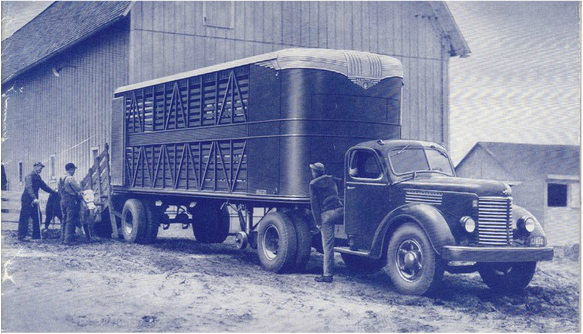

FLAT BED SEMI-TRAILERS

Boxed or raw freight, like lumber needed to be hauled on a flatbed semi-trailer platform without sides. These loads were invariably high weight and required steel reinforcement. These trailers came with I –Beam axles, mountain-type brake systems and main-plus helper springs. Some customers modified flatbed trailers with grain boxes or livestock cages for multiple uses. These semi-trailers eventually were used in the piggy-backing and fishy-backing systems created in the 1950’s which gave way to the later invention of the shipping container. For more on the flatbed trailer.....

Boxed or raw freight, like lumber needed to be hauled on a flatbed semi-trailer platform without sides. These loads were invariably high weight and required steel reinforcement. These trailers came with I –Beam axles, mountain-type brake systems and main-plus helper springs. Some customers modified flatbed trailers with grain boxes or livestock cages for multiple uses. These semi-trailers eventually were used in the piggy-backing and fishy-backing systems created in the 1950’s which gave way to the later invention of the shipping container. For more on the flatbed trailer.....

Guess who made the trailer??!

For more photos.....

Guess who invented the mudflap........

Mud Flaps come in all varieties of shapes, sizes and designs, from ribbed or smooth to decorative and promotional. For most of Fruehauf's dominance of the trailer market, mud flaps bearing the Fruehauf logo were ubiquitous on the nation's highways. Occasionally, I field the question, "Is your family the one who makes those rubber mud flaps?" Finally curiosity won us over and we embarked on a search for the real inventor of the "mud flap." Read Darlene Norman's take on mud flap history.

Click the hyperlinked photos or title for more info

Fruehauf paved the way to patent the shipping container in 1956

Click the hyperlinked photos or title for more info

Container shipping

Fruehauf partnered with McLean shipping, later Sea-Land Service to create the shipping container after WWII. After inventing the container Keith Tantlinger talked Fruehauf & McLean into giving the patented designs and technology to industry. This is when Tantlinger was working for Fruehauf, and his request began international standardization of shipping containers.

Earlier designs had been used that had flaws such as being too small. In 1956 the first recognized standard shipping container was offered to the transportation world, and Fruehauf opened that door, with the help of Keith Tantlinger and his immense talents and inventions.

Roy Fruehauf gathered the best and the brightest. He hired Keith Tantlinger in 1956 to serve as Fruehauf’s Vice President of Engineering and Manufacturing. Fruehauf received the patents for Tantlinger’s inventions, which included vehicle construction spring-to-axle mountings, bolster locking head for securing a semi-trailer to tractor fifth wheel, a container coupler and a pivoted draw-bar with lock. These and other patents were developed by Tantlinger and owned by Fruehauf. They all advanced container shipping to the efficient and successful process it is today. For more on Container history click here....

Fruehauf partnered with McLean shipping, later Sea-Land Service to create the shipping container after WWII. After inventing the container Keith Tantlinger talked Fruehauf & McLean into giving the patented designs and technology to industry. This is when Tantlinger was working for Fruehauf, and his request began international standardization of shipping containers.

Earlier designs had been used that had flaws such as being too small. In 1956 the first recognized standard shipping container was offered to the transportation world, and Fruehauf opened that door, with the help of Keith Tantlinger and his immense talents and inventions.

Roy Fruehauf gathered the best and the brightest. He hired Keith Tantlinger in 1956 to serve as Fruehauf’s Vice President of Engineering and Manufacturing. Fruehauf received the patents for Tantlinger’s inventions, which included vehicle construction spring-to-axle mountings, bolster locking head for securing a semi-trailer to tractor fifth wheel, a container coupler and a pivoted draw-bar with lock. These and other patents were developed by Tantlinger and owned by Fruehauf. They all advanced container shipping to the efficient and successful process it is today. For more on Container history click here....